A Durable Incinerator with

Smokeless Combustion and

High Operability for Safe Disposal of Medical Wastes

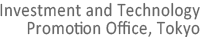

The incinerator “CHUWASTAR” has the water-cooled structure, where the main body of a furnace is covered with water jackets. This structure has excellent durability which is not damaged even if wastes of high calorific value such as plastics are incinerated.

In addition, the forced air supply method (combustion air is forcibly supplied into the furnace) enables prompt and smokeless incineration by supplying an appropriate amount of high-pressure air to the right position.

The main body consists of general steel plates with a simple assembly. Since ash outlets and a chimney are exposed to high temperature or acidic condition, hot dip aluminized steel plates are used to provide high durability and acid resistance.

Fig. 1 Entire image of CHUWASTAR (abbreviation in the chimney stack)

CHUWA INDUSTRIAL CO., LTD. provides quite useful incinerators with the instruction of commissioning. Dust collector and exhaust gas treatment equipment are a standard package. Energy saving (cogeneration) equipment like hot water boiler can be also installed to provide a facility of a shower, heating, washing, etc.

Major Features and Advantages

- Smokeless incineration is possible by anyone, at any time.

- A firm incinerator which endures reckless operation.

- Working environment is improved by the water cooling and the safety of workers is guaranteed.

- Scale of the incinerators is adjustable, depending on waste volume.

Technology Data

Possible applications

Medical waste disposal has been a significant issue in developing countries due to inappropriate handling. Therefore, the danger of the secondary infection by the infected wastes to hospital workers, patients, hospital visitors, and neighbors has been pointed out, and appropriate treatment facilities are desired.

The functions required as treatment facilities of the medical waste are the following;

– Complete sterilization

– Volume reduction

– Quick processing

CHUWASTAR is completely satisfied with these requirements. Water-cooled structure is excellent in durability, safe to use without risk of burns, etc. Also, it is a facility that can quickly achieve smokeless combustion without any special techniques, by the forced air supply method.

Fig. 2 Medical wastes in Sri Lanka

Fig. 2 Medical wastes in Sri Lanka

Competitive advantage

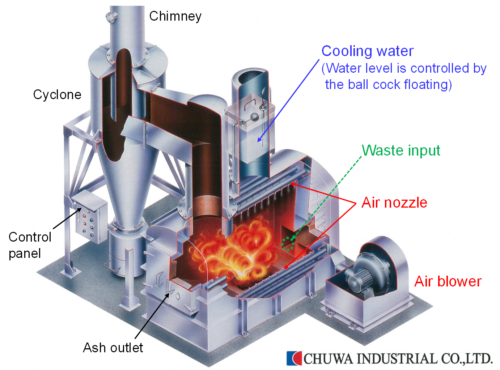

CHUWASTAR makes it possible to burn wastes of high calorific value such as plastics and rubber safely and easily. Also, it is an incinerator which succeeds in smokeless combustion. This is because CHUWASTAR is a water-cooled structure, the furnace body absorbs heat, so the working environment is safe and comfortable. (see Fig. 3)

Fig. 3 Water-cooled structure

Fig. 3 Water-cooled structure

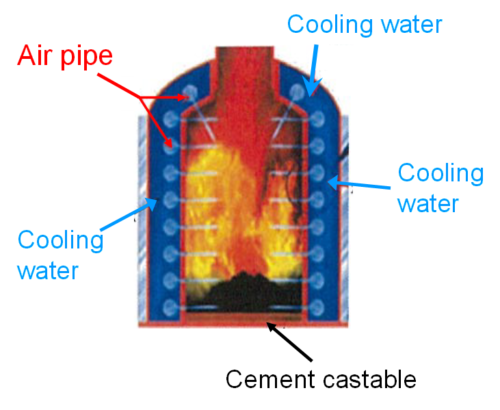

The smokeless operation is secured by the forced air supply method. As high-pressure air is discharged from the blower, plenty volume oy air goes through the air pipes and reaches to the air nozzles which are uniformly located to the external wall of the furnace. (see Fig. 4)

Fig. 4 Air blowing scheme

High pressure air is also injected to the chimney, which works as induction air like ejector, in order to prevent backfire and outflow of wastes from the furnace.

By utilizing these advantages mentioned above, the initial cost is relatively lower than other general incinerators. The running cost, which includes light oil, consumables of burner and other auxiliaries are also reasonable.

Performance

・Amount of waste input: 50~200kg/hour (depends on the area of the hearth)

・Smokeless incineration of most wastes is possible.

・The quantity of the combustion ash becomes 3-5% of the amount of waste input.

・Possibility of recovering of hot water, and can be used as an energy saving apparatus.

・Ignition burner and afterburner secure high-temperature combustion (850~1100℃) to prevent generation of dioxins.

・Safety interlocks are secured. (ex. “Low water level” detected by electrode bipolar system makes a buzzer alarm. When water level is lower than the limit, blowers are stopped to extinguish a fire.)

Technical maturity / Past record of introduction

・Exported to 26countries, including African countries (the Democratic Republic of Congo, the Kingdom of Morocco)

・The total number of exported products are 460 units.

・Exports as the incinerator of medical wastes has been increasing

・CHUWA INDUSTRIAL CO., LTD has partnering companies in Vietnam, Thailand, Sri Lanka and China to enhance sales and customer service.

Information on patent related to this technology

N/A

Company Data

| Name | CHUWA INDUSTRIAL CO., LTD. M.K.D. Corporation |

| Address |

OG Bldg.3F, 2-8-7, Nihonbashihoncho, Chuo-ku, Tokyo, Japan (CHUWA INDUSTRIAL CO., LTD.) |

| Capital | 10 million yen (as of March 2019, CHUWA INDUSTRIAL CO., LTD.) 3 million yen (as of March 2019, M.K.D. Corporation) |

| Contact person |

Mr. Kuniaki IMAO (CHUWA INDUSTRIAL CO., LTD.) |

| Number of employees |

6 (as of March 2019, CHUWA INDUSTRIAL CO., LTD.) |

| Date of company foundation |

1st October 1969 (CHUWA INDUSTRIAL CO., LTD.) |

| Type of business |

Design, planning and sales of incinerators (CHUWA INDUSTRIAL CO., LTD.) |

International operation

| Number of employees for international operation |

3 |

|

| Overseas offices |

City, Country | Name of Company (if applicable) |

| N/A | N/A | |

Modality of business transaction

Partnership

We will plan deployment with a consideration of locally-based production in a country with large population. (China, India, Indonesia, etc.)

Export of product

We will plan deployment with a consideration of locally-based production in a country with large population. However, we will plan the installation of finished products in a country with small population.

Attachments

Schematic illustration of the technology

Fig. 5 Entire image of CHUWASTAR (left: CX-800 type, right: CX-300 type)

Fig. 5 Entire image of CHUWASTAR (left: CX-800 type, right: CX-300 type)

Product information

CHUWASTAR CX type catalogue

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Waste treatment and management