Joint Packing for the Leakage-Free Water Pipes by Preventing Uneven Tightening of Flange Bolts That Causes Water Leakage and Packing Rupture

Joint Packing for the Leakage-Free Water Pipes by Preventing Uneven Tightening of Flange Bolts That Causes Water Leakage and Packing Rupture

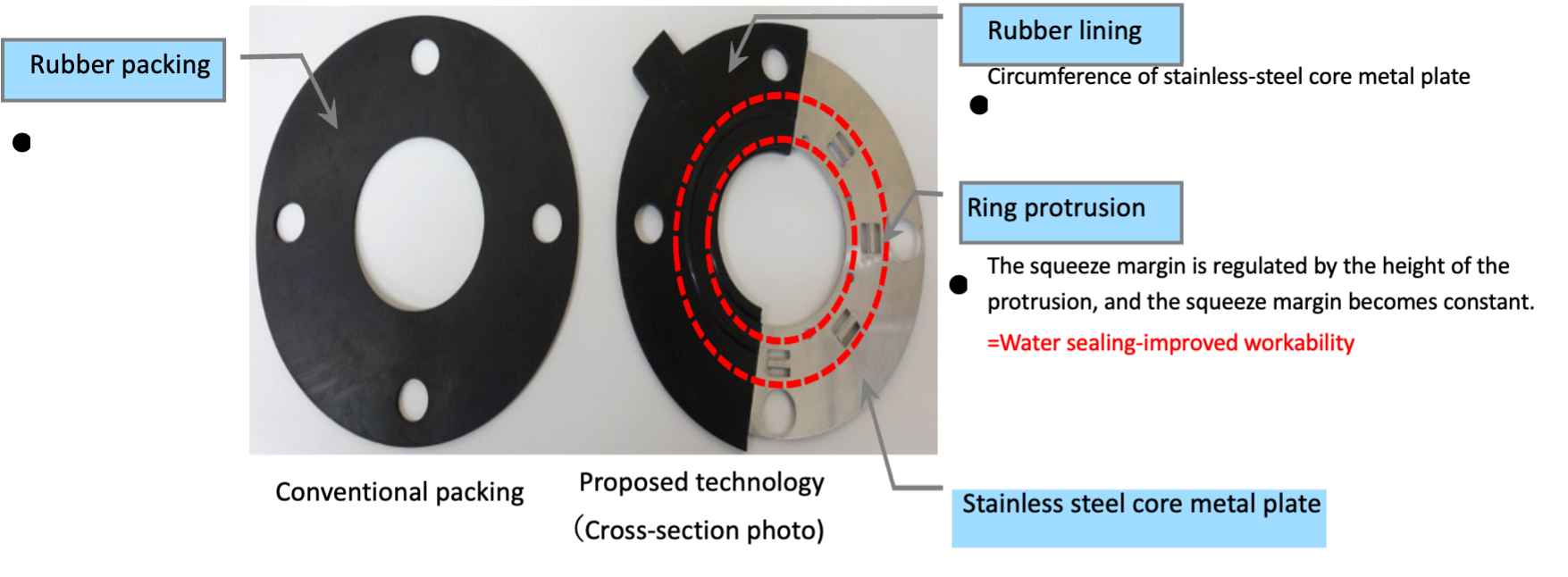

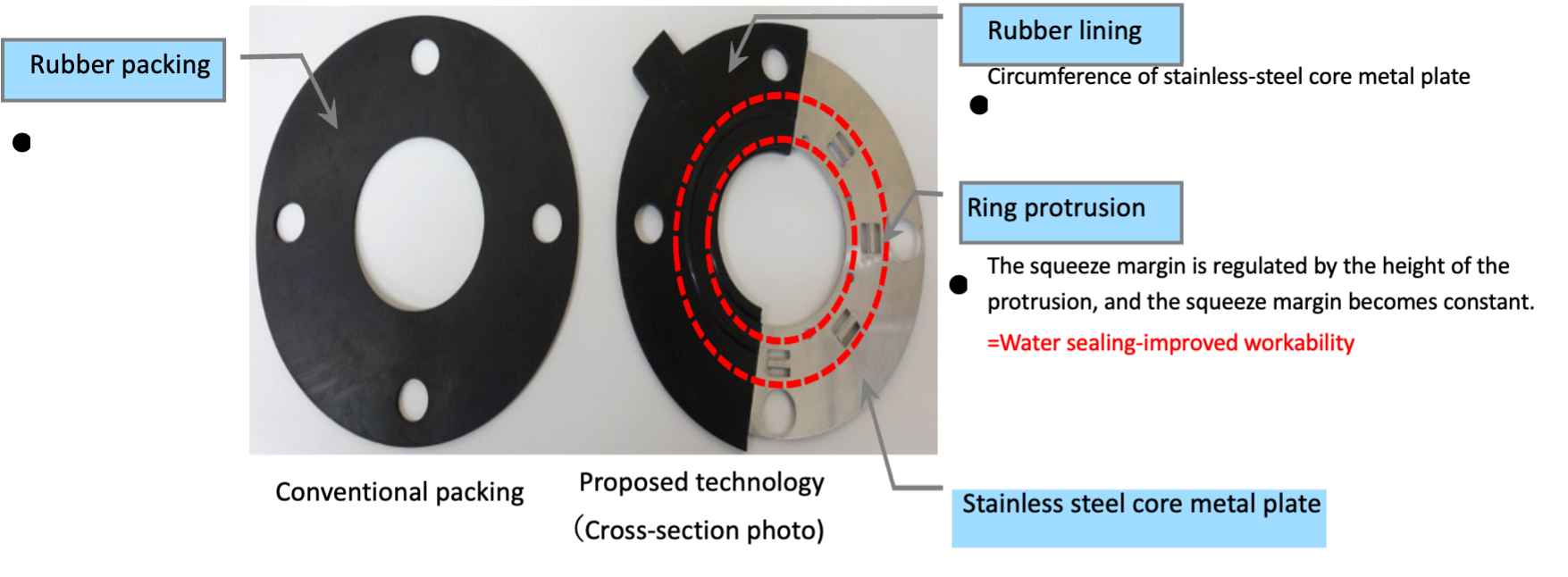

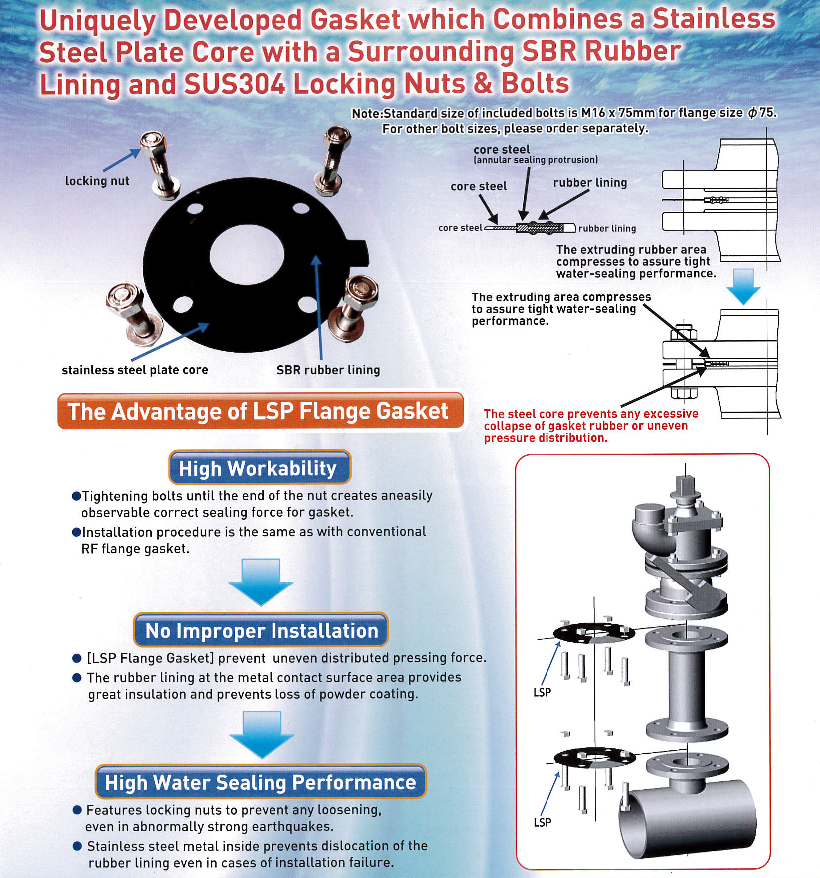

This is a packing for connecting piping flanges. It is a product that combines a packing with a specially structured stainless steel core metal plate covered with rubber and loosening prevention bolts and nuts. It has excellent workability and water leakage resistance.

Major Features and Advantages

- The device prevents uneven tightening which causes water leakage and enables the construction of water pipes with fewer risks of water leakage.

- The quality of installation is assured by its design which minimizes the influence of skill variations of workers.

- It prevents packing rupture which occurs in the event of an earthquake.

- It stops water in a reliable manner even in the case of bolt fastening failure.

- The resistance to water leakage is even enhanced by the use of looseness preventive bolts and nuts.

Technology Data

Possible applications

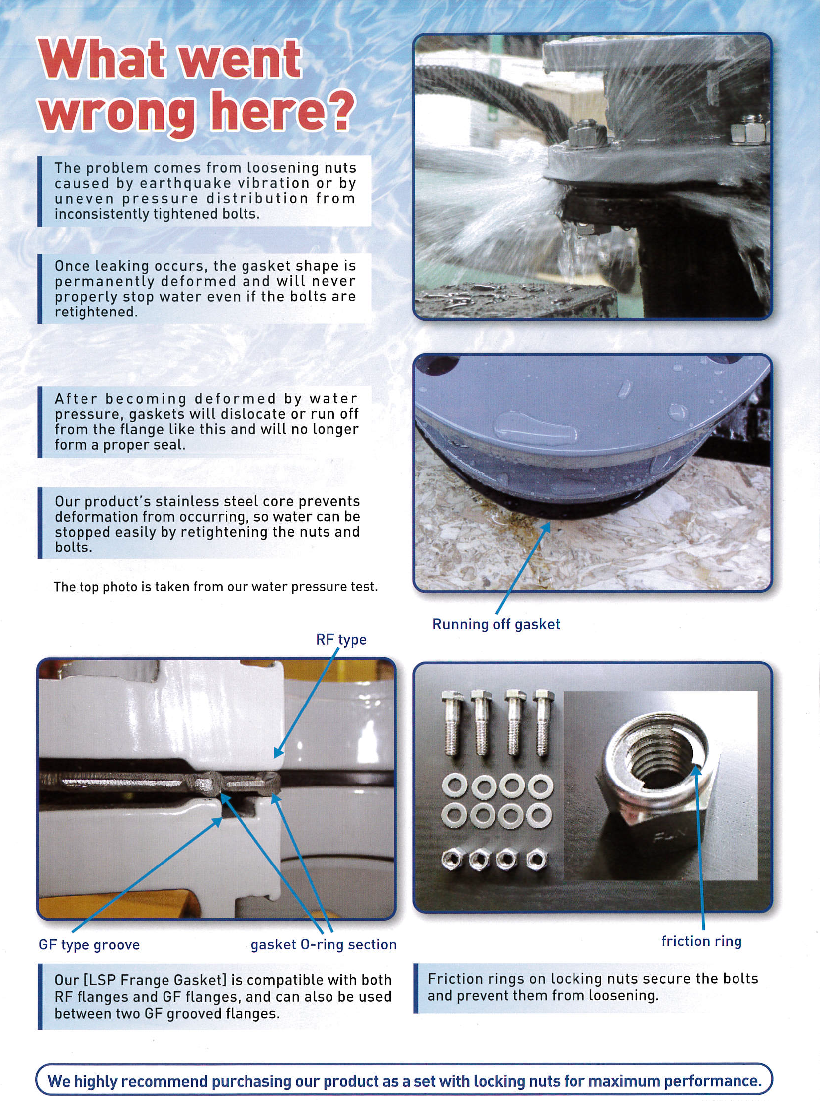

“Reinforcing joint packing for flanges: LSP” is a product that combines “packing with a specially structured stainless steel core metal plate covered with rubber” and “locking bolts and nuts”. When joining flanges, the core metal plate with a special structure of LSP regulates the squeeze margin and keeps the squeeze margin of rubber constant to prevent one-sided tightening and uneven tightening that cause water leakage. It can also improve earthquake resistance. This makes it possible to construct water pipes that do not leak water even if there is a bolt fastening failure (insufficient fastening torque) due to the differences in worker’s skill.

In developing countries, the water infrastructure market is expected to continue growing in the future, and some countries have more earthquakes than Japan. The strongest features of this technology is its earthquake resistance and the simplicity of the installation that does not require specialized skills. These features are extremely effective in Japan where the workers are trained and implement stable installations, but even more so in developing countries where the skill variation of workers may be unstable. This technology will enhance the durability and contribute to the protection of important lifelines and infrastructure in the event of an earthquake.

Competitive advantage

“Reinforcing joint packing for flanges: LSP” is a product that combines “packing with a specially structured stainless steel core metal plate covered with rubber” and “locking bolts and nuts.” Compared to general packings, it is more water resistant and has an excellent workability as well as earthquake resistance. When tightening this product with bolts, a special structure stainless steel core metal plate regulates the squeeze margin (the patented special structure stainless steel core metal plate keeps the rubber squeeze margin constant and causes water leakage. It is possible to prevent one-sided tightening and uneven tightening), so the entire packing can be tightened evenly. This makes it possible to construct piping that does not cause water leakage without depending on the skill of the operator. In addition, the cause of the packing bursting and water leakage in the event of an earthquake can be prevented by uniform tightening and the core metal plate.

|

Feature |

General packing |

LSP flange coupling reinforcement |

|---|---|---|

| Water cut-off performance and workability |

⇒The finish and quality of plumbing depends on the skill of the worker. |

⇒ Highly water-stopping construction is possible without depending on the skill of the worker |

| Seismic resistance |

|

|

Performance

Technical evaluation result

- Even if the tightening torque of the bolts that fasten the flange is insufficient (30% of the specified value) or forgotten to fasten (1/2 of the number of bolts), the water stop effect can be obtained.

- Even if bolts are tightened with excessive tightening torque (1.5 times), the rubber part will not be damaged. Secure 100% of water sealing

- As a packing strength evaluation, the specified torque is opened and closed 100 times.

- The local load is applied locally to the iron plate of 3 x 5 cm, the surface pressure is 57 N / mm2, and the water sealing performance is 100% even if the clamp is opened and closed 50 times.

Reinforcing joint packing for flanges, considering the performance and achievements of the material: After LSP construction, it can ensure the same durability as the service life of the pipeline unless it is disassembled.

Technical maturity / Past record of introduction

Eight years after the start of sales, it has been adopted by about 454 out of about 1400 companies nationwide. Annual sales of 10,000 sheets (size: φ75 to φ450).

Information on patent related to this technology

6046812

6405559

WO 2014192442.A1

Trademark registration 5667001 「LSP」

Trademark registration 5667000 「Lock suspension packing」

Company Data

| Name | Kyowa Industrial Co., Ltd. |

| Address | 1790 Kotakari-cho, Higashiomi-city, Shiga,527-0125, Japan |

| Capital | 85 million JPY (as of 30 June, 2021) |

| Contact person | Mr. Katsuya SHIMIZU E-Mail: katsuya@kyowakk.com TEL: +81-749-45-0561 |

| Number of employees | 25 (as of 30 June, 2021) |

| Date of company foundation | 11 July, 1961 |

| The type of business | Manufacture and sale of water valve plugs |

International operation

| Number of employees for international operation |

N/A | |

| Overseas offices | City, Country | Name of Company (if applicable) |

| N/A | N/A | |

Modality of business transaction

Partnership

A joint venture with a local partner company (packing maker) will be established to locally produce LSP flange joint reinforcements and sell them to water construction companies that carry out new construction and repair work on water pipes.

For sales, the existing sales channels of local partner companies will be utilized.

As a production facility, a press processing machine and a mold for molding packing are required. As for press processing machines, specific specifications (those that can be evacuated) are required, so a packing maker that owns a press processing machine that meets these specifications will be selected as a local partner company.

As for the mold, since it will be the core part of the proposed technology, we will procure it from a Japanese mold manufacturer who has been developing LSP flange coupling reinforcements together with the proposing corporation.

The stainless-steel core metal plate is manufactured by a local sheet metal manufacturer.

Direct Investment

Entrust product market development and sales with a local partner company as a sales agent.

Licensing of patent

Patent licensing to businesses that have or can secure local manufacturing technology.

Attachments

Schematic illustration of the technology

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Agribusiness Technologies : Water resource management

- Disaster Management Technologies : Disaster prevention and preparedness