Maximize Battery Life with

Long-Duration Energy Storage

NGK INSULATORS, LTD. has introduced a Sodium Sulfur Battery System technology -- NAS® battery -- that is currently the only commercially mature, large-scale energy storage technology that can be installed anywhere. NAS battery can be used for a variety of clients, including:

・Power plants

・Power plants

・Substations

・Industrial

・Commercial

・Residential

With output/capacity of 530 MW/3700 MWh effectively stored worldwide, NAS battery offers its capacity for peak shaving, load leveling, and emissions reductions. Backed by a reliable design and safe operation, NAS battery is the most effective battery to store large amounts of electric energy (six hours at rated output).

NAS batteries comprise sulfur at the positive electrode and sodium at the negative electrode, with the electrolyte being a sodium ion conductive ceramic made up of beta-alumina. From large capacity and high-energy density to long life and small size, there are many advantages to this technology.

Major Features and Advantages

I. Versatility

NAS battery is used in a variety of applications, such as peak shaving, load leveling and emissions reductions. They may be utilized in power supplies and as the central feature of a smart grid, or to provide power for ancillary services, grid frequency controls, and reactive power compensation.

II. Large Capacity

Being able to provide power for six hours or more, a single NAS battery system can be used for long energy shifting, peak shaving, grid frequency control and emergency power supply.

III. Compact

The 200-kW/1200-kWh battery is compact and easy to store, available in a 20-ft ISO shipping container. Thanks to fully containerized battery units, clients can save money on transportation and construction.

IV. Durability and Long Life Span

NAS battery has less capacity deterioration and no need for battery replacement until the end of its life (about 15 years or 4,500 cycles). The batteries work in many environments, with ambient temperatures between -20 ~+45C degrees.

V. Eco-Friendly

Because sodium and sulfur are abundant throughout nature, raw material depletion is not a concern. Clients who are concerned about the impact on the environment can rest easy knowing these raw materials will always be in abundance.

VI. Easy Operation and Maintenance

With no self-discharge and no uniform charge required, preventive maintenance is minimal because consumable parts only need to be replaced periodically. It’s also possible to schedule maintenance which will avoid interruption at peak operation.

Sodium sulfur batteries produced by NGK Insulators Ltd. offer an established, large-scale energy storage technology with the possibility for installation virtually anywhere. With a wide array of advanced features, from large capacity to compactness, NAS battery is a welcome addition into the long-duration energy storage industry.

Technology Data

Conceivable Applications

Sodium sulfur (NAS®) batteries produced by NGK

Insulators Ltd. (NGK) are presently the only

commercially mature, large-scale energy storage technology that can be installed anywhere.

The active materials in NAS batteries are sulfur at the positive electrode and sodium at the negative electrode, and the electrolyte is a sodium ion conductive ceramic composed of beta-alumina. NAS battery systems boast an array of advanced features, such as large capacity, high energy density, long life, and compactness.

NGK markets NAS batteries for use in grid storage (especially for use in conjunction with intermittent renewable energy sources such as wind and solar). The battery systems have applications in peak shaving, load leveling, and emissions reductions. They can be used as emergency power supplies, or they can provide power for ancillary services, grid frequency controls, and reactive power compensation. They can also serve as the central components

of a smart grid.

Competitive Advantage

Large Capacity

NAS battery has more than 6 hours of capacity. A single battery system can be used for long energy shifting, peak shaving, grid frequency control, emergency power supply, and multiple other applications.

Compactness

The 200-kW/1200-kWh battery is available in a 20-ft ISO shipping container.

Plug & Play solutions

Users can noticeably save transportation and construction costs with fully containerized battery units.

Long Life and Durability

Less capacity deterioration with no need for battery replacement until the end of life (4,500 full cycles or 15 years). NAS batteries work in a wide range of ambient temperatures (-20 ~+45C°) *1.

*1: The acceptable ambient temperatures can be increased to -45 ~ +55 C°by specific design modification upon customer request.

Many Years of Field Service

NGK’s NAS battery has been commercialized since 2002, and the total global installation figure is approx. 530 MW/3700 MWh.

Easy Operation and Maintenance

There is no self-discharge, and uniform charge is not required.

Preventive maintenance is minimal since only consumable parts should be periodically replaced. Furthermore, maintenance can be scheduled to avoid peak operational seasons.

High Safety and Reliability

The safety of NGK’s NAS battery cell is proven through its having earned the UL label in The US. The NAS Battery system also has the CE label in the E.U.

No concerns regarding raw material depletion

Sodium and sulfur (the major raw materials for NGK’s NAS battery) exist naturally in the world, so there are no concerns of raw material depletion.

Performance

A summary of the NAS battery features are listed below;

・Large capacity: rated power x 6 hours

・High energy density: 1.4 kWh/m3, 57.1 Wh/kg as a 20ft Container

[As a reference for footprint, 47 m2 /MWh-ac including BoP (as a recent actual result at Buzen, Kyushu, Japan)]

・Fast response: within one (1) millisecond (full power charge to full power discharge, full power discharge to full power charge)

・Long life: 15 years or 4,500 full discharge (100% Depth of Discharge) cycles

・No self-discharge; No need for uniform charge

・Applicable to a wide range of ambient temperatures (-20 ~+45C°)*1

*1: The acceptable ambient temperatures can be increased to

-45 ~ +55 C°by specific design modification upon customer request.

Technical maturity

The current total worldwide installed capacity (including under construction) of NGK’s NAS battery systems is approx. 525 MW (3,560MWh), as of March 2018. (The following table shows the breakdown by region.)

| Output | Energy | |

| Japan | 360 MW | 2510 MWh |

| Europe | 37 MW | 260 MWh |

| North America | 20 MW | 140 MWh |

| UAE(*) | 108 MW | 650 MWh |

(*)Including sites under construction.

Conceivable risk

Appropriate maintenance work should be executed in accordance with NGK’s maintenance procedure. In

case users do not properly handle the maintenance work, they could fail to realize the product’s expected performance.

Information on patent related to this technology

Five representative patents:

(JP) P4750549

(JP) P4574196

(JP) P4289948

(JP) P4076331

(JP) P3329700

*Total active patents: 149 (as of March 2018)

Company Data

| Name | NGK INSULATORS, LTD. |

| Address | 2-56 Suda-cho, Mizuho, Nagoya 467-8530, Japan |

| Capital | JPY 69.8 billion (as of March, 2017) |

| Contact person |

Mr. Kodai Okano |

| Number of employees |

Consolidated |

| Date of company foundation | May 5, 1919 |

| The type of business | Manufacture and sale of electric power related equipment including insulators, and of ceramic catalyst carrier for exhaust gas purification, and of industrial products, and of beryllium copper products |

International operation

| Number of employees for international operation |

Consolidated: 13,658 (as of March 15, 2018) |

|

| Overseas offices |

City, Country | Name of Company (if applicable) |

| Salford, England | NGK BERYLCO U.K. LTD. | |

| Baudour, Belgium | NGK CERAMICS EUROPE S.A. | |

| Taunus, Germany | NGK EUROPE GmbH | |

| NGK DEUTSCHE BERYLCO GmbH | ||

| Gliwice, Poland | NGK CERAMICS POLSKA SP. Z O.O. | |

| Couëron, France | NGK BERYLCO FRANCE. | |

| CapeTown, South Africa | NGK CERAMICS SOUTH AFRICA(PTY)LTD. | |

| Hebei, China | NGK INSULATORS TANGSHAN CO., LTD. | |

| Shanghai ,China | NGK INSULATORS (CHINA) INVESTMENT CO., LTD. | |

| Jiangsu, China | NGK TECHNOCERA SUZHOU CO., LTD. | |

| Seoul, Korea | NGK AUTOMOTIVE CERAMICS KOREA CO., LTD. | |

| Haryana, India | NGK TECHNOLOGIES INDIA PVT. LTD. | |

| Bekasi, Indonesia | P.T. NGK CERAMICS INDONESIA | |

| Saraburi, Thailand | SIAM NGK TECHNOCERA CO., LTD. | |

| Victoria, Australia | NGK STANGER PTY. LTD. | |

| Baltimore, MD, U.S.A. | NGK-LOCKE INC. | |

| Virginia Beach, VA, U.S.A. | NGK-LOCKE POLYMER INSULATORS, INC. | |

| Mooresville, NC, U.S.A. | NGK CERAMICS USA, INC. | |

| Novi, MI, U.S.A. | NGK AUTOMOTIVE CERAMICS USA, INC. | |

| Fremont, CA, U.S.A. | FM INDUSTRIES, INC. | |

| Santa Clara, CA, U.S.A. | NGK ELECTRONICS USA, INC. | |

| South Sweetwater, TN, U.S.A. | NGK METALS CORPORATION | |

| Ontario, Canada | NGK INSULATORS OF CANADA, LTD. | |

| Nuevo León C.P., México | NGK CERAMICS MEXICO, S. de R. L. de C. V. | |

Modality of business transaction

Partnership

NGK would like to export the product and entrust the maintenance work to the local partner after completion of NGK’s maintenance training to the local partner.

Export of product

NGK would like to directly export our products from Japan at the beginning stage. However deployment of local sales representative can also be considered depending on market demand.

Attachments

Schematic illustration of the technology

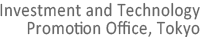

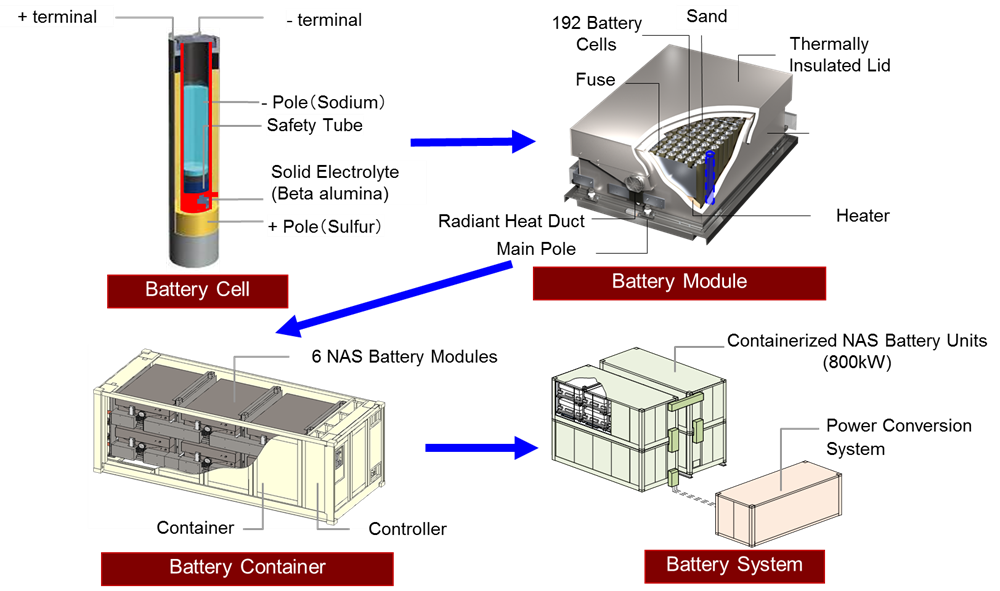

Figure 1: Principles of Sodium Sulfur Batteries

NAS batteries consist of a beta-alumina solid electrolyte, sodium as the negative electrode, and sulfur as the positive electrode. Figure 1 shows the discharge and charge reactions for the NAS battery. During discharge, sodium ions move from the negative electrode to the positive electrode through the beta-alumina, creating sodium polysulfide. When charging, the sodium ions return to the negative electrode. The internal temperature of the battery module is kept at around 300 °C by the electric heaters equipped in the thermal insulated enclosure, to maintain all active materials in a liquid state.

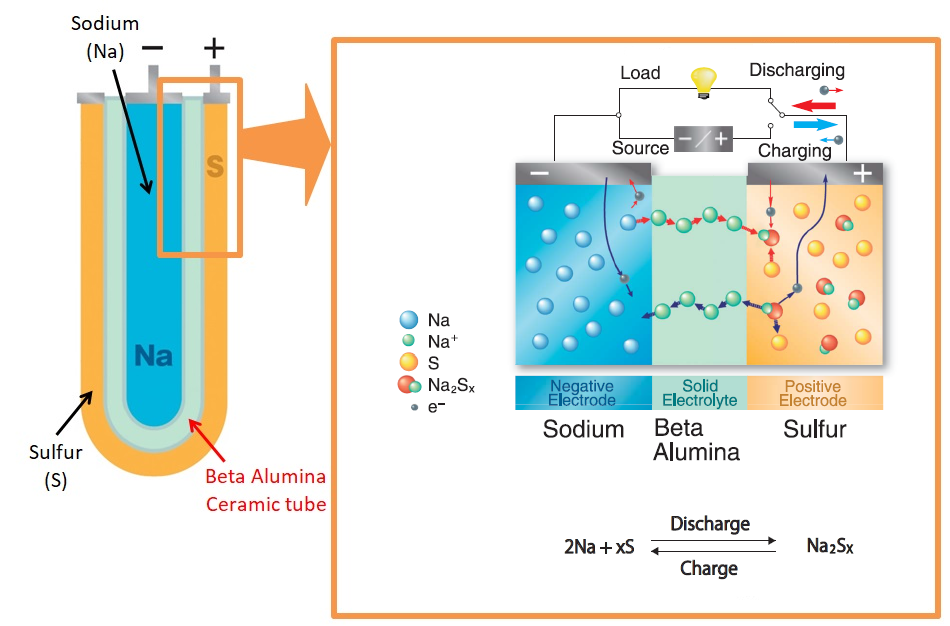

Figure 2: Structure of Containerized NAS Battery Systems

The battery cell is cylindrical in shape and consists of sodium at the center and sulfur at the outside. A module contains many cells within a vacuum insulated thermal enclosure in which the temperature is properly controlled. The outer double-layer vacuum insulation minimizes heating power, dramatically improving system efficiency. A 200-kW (1,200-kWh) Containerized Battery consists of six (6) integrated battery modules and controllers in a 20-foot shipping container. This standard 20-foot ISO container can be transported by sea, vehicle, or train. The 200-kW container can be connected in series with up to four (4) containers to compose up to an 800-kW subsystem. Figure 2 shows the structure of this containerized NAS battery system.

For further information, a product outline, brochures, movies, specs, and case studies, visit the following URL:

https://www.ngk.co.jp/nas/

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Energy Technologies : Renewable energy / Energy saving and energy storage