Mercury Waste Recycling

Mercury Waste Recycling

Technology: Advancements in

Waste Management Technology

Through the collection of mercury, one Japanese company says it can prevent environmental pollution and corresponding health concerns. Nomura Kohsan Co., Ltd. is marketing a technology that allows for the proper collection and recycling of mercury, an extremely poisonous element to humans. You’ll find mercury in many common items, from fluorescent lamps and batteries to blood pressure devices and thermometers. If inhaled, ingested, or contracted through an open wound, it can damage the nerves, liver and kidney, with symptoms such as muscle weakness, poor coordination, rashes, anxiety, memory problems, and difficulty seeing, hearing or speaking.

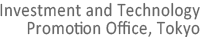

Recovered through a roasting process, mercury can be vaporized from the waste it is contained in. This roasting process involves hearting an object so much that its physical or chemical properties change. However, even at such high heats, it’s important not to melt the substance. Nomura Kohsan roasts the mercury to a temperature between 600℃ and 800℃ to vaporize the mercury in waste. Then, the mercury vapor is recovered after it is encouraged to flow through a cooling tower and scrubber. There is a concern that small traces of mercury can get into the atmosphere, something that researchers have always been conscious of. However, to prevent this from happening, Nomura Kohsan uses a mercury adsorbent in the final process.

Major Features and Advantages

I. Prevention of Environmental Pollution and Health Concerns

This technology is designed to prevent environmental pollution and corresponding health concerns associated with mercury poisoning. As the only company in Japan with a facility that can adequately and safely recycle, treat and process mercury waste, Nomura Kohsan offers an extremely rare technology on a global basis, positioning itself for unique application.

II. Adherence to Strict Standards

The strict standards of the company even meet the requirements of Japan’s National Effluent Standards of 0.005 mg/L, which is a standard applied to landfill disposal requirements. Furthermore, the Minamata Convention on Mercury speculates there will be an increase in surplus mercury and subsequent demand for solidification and stabilization processes. Nomura Kohsan has responded in kind by conducting tests and research on these technologies that have also cleared the National Effluent Standards.

III. Ability to Recycle

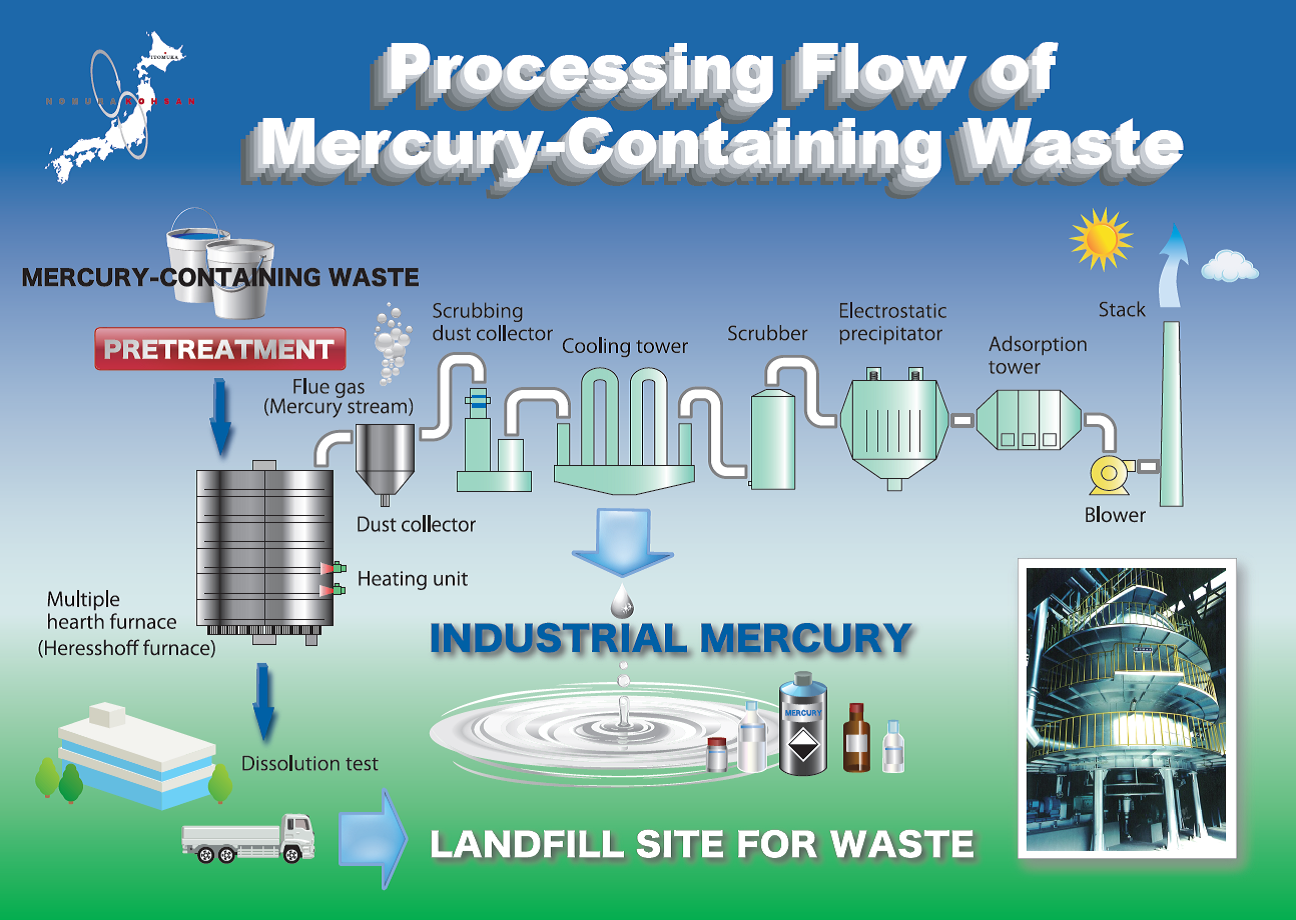

The positive outcome to this process is that the mercury is effectively removed from waste, yet the rest of the waste product can still be recycled. For example, from fluorescent lamps, glass, metallic base, and fluorescent powder can be recycled.

IV. Wet Process

Nomura Kohsan uses a wet process thanks to the capacity to treat mercury-containing liquid waste. Typically, companies use a dry process for treating used fluorescent lamps. Utilizing a wet process, however, allows for nearly 100% recycling.

V. Cooperation in Mercury Waster Treatment and Recycling Activities

Nomura Kohsan, through the signing of a memorandum of understanding with UNIDO in April 2014, will cooperate on projects that manage waste from mercury and pass on this technology to developing countries. The main focus remains South East Asian countries, where the company promises to cooperate in mercury waste treatment and recycling activities there. Nomura Kohsan goes one step further and has a membership in the UNEP Global Mercury Partnership on Waste Management and Supply and Storage.

Nomura Kohsan, established in 1973, has been treating, processing and recycling mercury waste for more than 40 years.

Technology Data

Conceivable applications

By properly collecting and recycling mercury— which is contained in many widely used products such as fluorescent lamps, batteries, mercury blood pressure devices and thermometers—we can prevent environmental pollution and damages to our health.

Mercury is recovered through a roasting process. “Roasting” is when we heat an object to the extent where physical or chemical change is created (but without melting it). At Nomura Kohsan, we roast at 600℃~800℃ in order to vaporize the mercury that is contained in the waste. Afterwards, the mercury vapor flows through a cooling tower and a scrubber where it is recovered. Furthermore, to thwart even the smallest trace of mercury from getting into the atmosphere, we have equipped the final process with mercury adsorbent.

By properly removing mercury from the waste, other materials from the waste product can be recycled.

Competitive advantage

Nomura Kohsan is the only company in Japan with an all-inclusive facility that has the capacity to recycle, treat and process a wide variety of mercury waste. Such company is also rare, globally. Furthermore, despite Japan’s National Effluent Standards of 0.005 mg/L (a standard used for landfill disposal) being one of the world’s most stringent standards, our treatment process meets the requirements of this standard.

More recently, with the Minamata Convention on Mercury, it is perceived that there will be an increase in surplus mercury and as a result a demand for solidification and stabilization processes. We have conducted tests and research on these technologies and have cleared the National Effluent Standards.

Although the dry process for treating used fluorescent lamps is more mainstream, we employ the wet process since we have the technology to treat mercury-containing liquid waste. With this technology, we are capable of treating all types of fluorescent lamps, and nearly 100% of the lamp is recycled.

Nomura Kohsan has signed a memorandum of understanding with UNIDO in April 2014. We have agreed to cooperate on projects that manage waste from mercury and to disseminate technology to developing countries. South East Asian countries will be our main focus, where we will be actively cooperating in the mercury waste treatment and recycling activities.

Lastly, we are also a member of the UNEP Global Mercury Partnership on Waste Management and Supply and Storage.

Performance

■ For fluorescent lamps

Once the lamps are crushed, the metallic bases are removed and the Hg-contaminated glass fragments pass through the washing process. Through this process, Hg-contaminated sludge is collected, which is then sent to the furnace for roasting (for more information on roasting process see “conceivable application”). In addition to this, fluorescent powder (which is collected during the crushing process) contains traces of Hg, so it also goes though the roasting process in order to retrieve mercury.

Recovered materials are recycled into the following products:

Mercury ⇒ used in fluorescent lamps, reagent, etc.

Glass ⇒ raw material for: glass wool (fiberglass), glass (for fluorescent lamps), and cement

metallic base ⇒ raw material for aluminum

fluorescent powder ⇒ raw material for rare earth

Percentage (of the whole lamp) recycled: nearly 100%

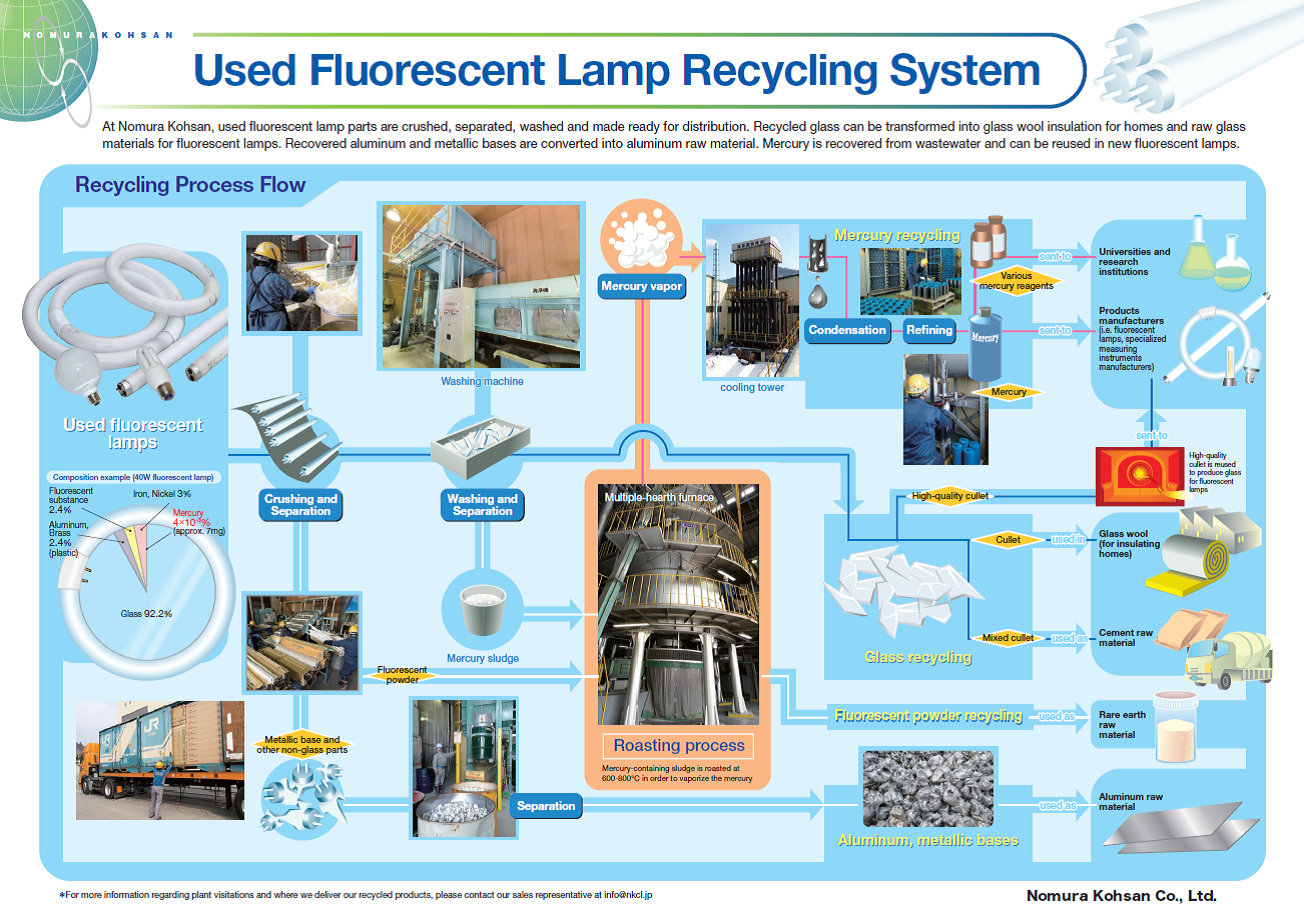

■ For dry-cell batteries

Secondary batteries are removed through a two-step process of sorting (shape-based sorting and manual sorting). Afterwards, they are sent to specialized companies for recycling.

Only primary batteries are processed at our facility. First, the batteries go through a roasting process in the rotary kiln so that the mercury can be vaporized and recovered. Then, the roasted remnants are pulverized and magnetically separated, isolating the iron scraps from the residual zinc and manganese.

Recovered materials are recycled into the following products:

Mercury ⇒ used in fluorescent lamps, reagent, etc.

outer casing (iron scrap) ⇒ raw material for iron

Residual zinc and manganese ⇒ raw material for zinc ingot and micronutrient fertilizer

Percentage (of the whole battery) recycled: nearly 100%

Technical maturity / Past record of introduction

We have inherited the technology and equipment of Nomura Mining (est. 1939)—a company that operated a mercury mine for nearly 35 years. The company and mine closed down and Nomura Kohsan was established in 1973. Since then, for over 40 years we have specialized in treating, processing and recycling mercury waste.

Treatment and processing record from the past 3 years

FY 2013: approx. 25,000t (2013.4.1~2014.3.31)

FY 2012: approx. 27,000t (2012.4.1~2013.3.31)

FY 2011: approx. 26,000t (2011.4.1~2012.3.31)

Past record of waste imported from abroad

Taiwan:

Dry cell batteries, button cell batteries, HID lamps: approx. 3,200t (2006~ 2014.6)

Philippines:

Fluorescent lamps: approx. 60t (2002~2014.6)

Until now, we have been importing uncrushed lamps from the Philippines and have been treating and recycling the lamps in Japan. However, in 2014, with the support of the Ministry of Economy, Trade and Industry of Japan (METI) we have established a new recycling scheme for the Philippines. We installed a lamp crusher in the Philippines, thus allowing lamps to be crushed locally. The crushed lamps will be shipped to our facility.

Through this local pre-treatment process, we will be able to reduce the transportation fee, which in turn, will cut the cost of the whole recycling process. Moreover, by setting up a pre-treatment facility, we aim to raise awareness and increase the recycling rate in the Philippines.

Conceivable risk

Whether the notion of having to pay a fee to recycle waste can be rooted into society

Whether it would be possible to establish a collection method in the local community

(Once technology is transferred and an intermediate processing center is established) whether local sales destination for recycled products can be secured

Information on patent related to this technology

N/A

Company Data

| Name | Nomura Kohsan Co., Ltd. |

| Address | 1-3, Nihonbashi Horidomechou 2-chome, Chuou-ku, Tokyo 103-0012 Japan |

| Capital | JPY 182,095,000 |

| Contact person | Mr. Yasuyuki YAMAWAKE Tel.: +81-3-5695-2530 Fax: +81-3-5695-2540 E-mail: info@nkcl.jp |

| Number of employees | 245 (3 for international operation) (As of April 1, 2014) |

| Date of company foundation | December 10th, 1973 |

| The type of business | Mercury waste recycler |

Modality of business transaction

Partnership

To establish a partnership contract with local waste collectors and export collected waste to Japan. In the future, we would like to transfer technology so that intermediate processing of waste can be done locally.

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Pollution Prevention and Control / Waste treatment and management