Water-Saving Porous Alpha

Technology Increases Crops

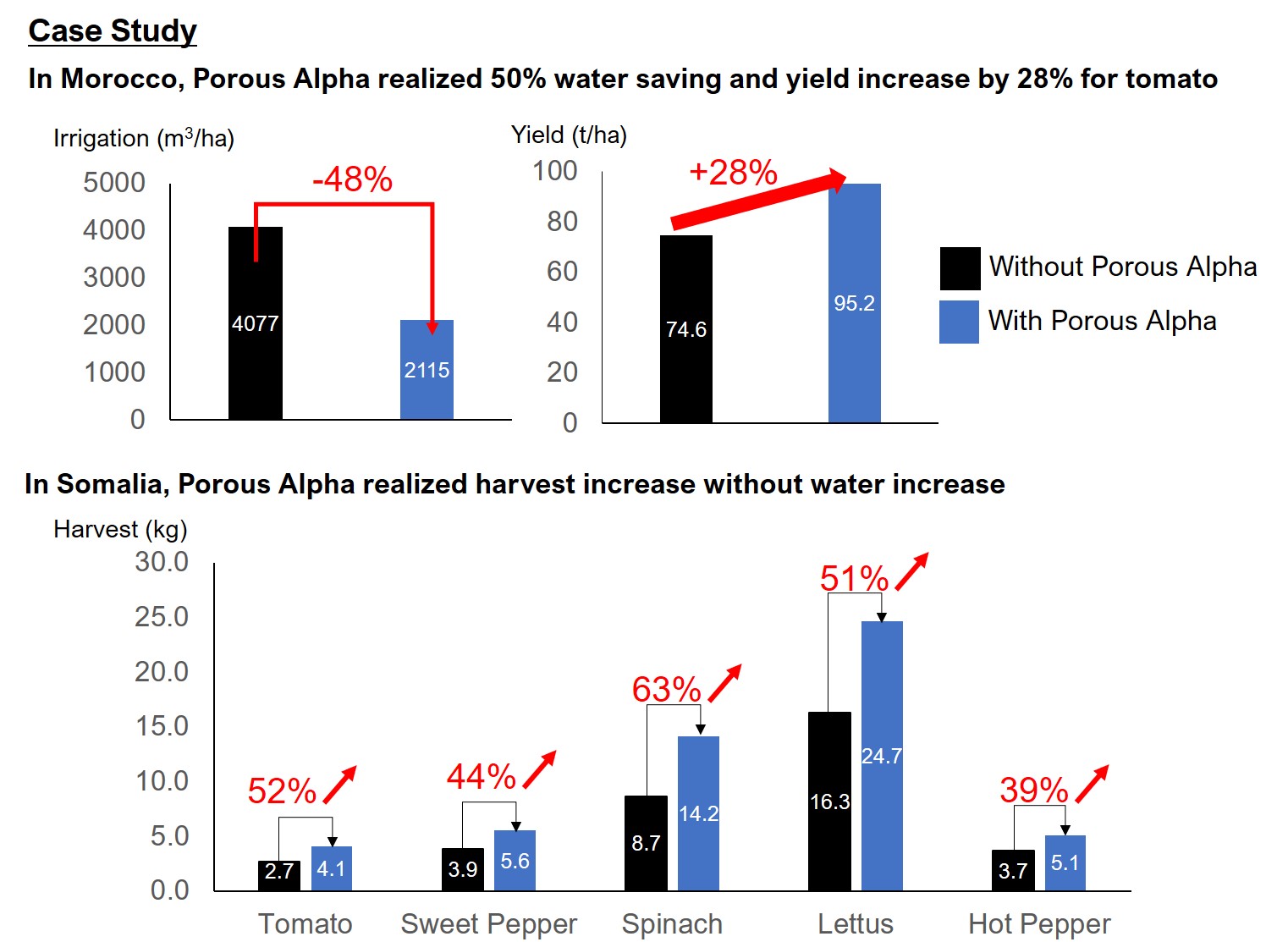

TTo improve food security, Tottori Resource Recycling Inc. wanted to utilize our technology that could make people independent. That’s where the environmentally friendly innovative foamed glass “Porous Alpha” comes in. By just mixing Porous Alpha in the soil, water-saving cultivation in dry areas is provided because Porous Alpha holds water in the soil and improves the water retention capacity. In the trials carried out in a greenhouse in Morocco, the crop yield increased by 20% with 50% less water consumption.

The main raw material of Porous Alpha is used glass bottles and solar panel glass. They are crushed into a powder, then calcium carbonate is added. Once heated, the material becomes amorphous and porous. This structure allows it to retain water and liquid fertilizer. Porous Alpha provides water and fertilizer to plants when they are needed, which is the unique property to this technology.

The main component of the raw material of Porous Alpha, glass bottle and solar panel glass is silica, and calcium carbonate, which is the same as the natural sand, and it is manufactured by the patented safe glass foaming technology. Also, with the patented safe glass foaming technology, there is no negative impact on soil or crop. Consequently, Porous Alpha comprises only natural materials, and it doesn’t harm the environment.

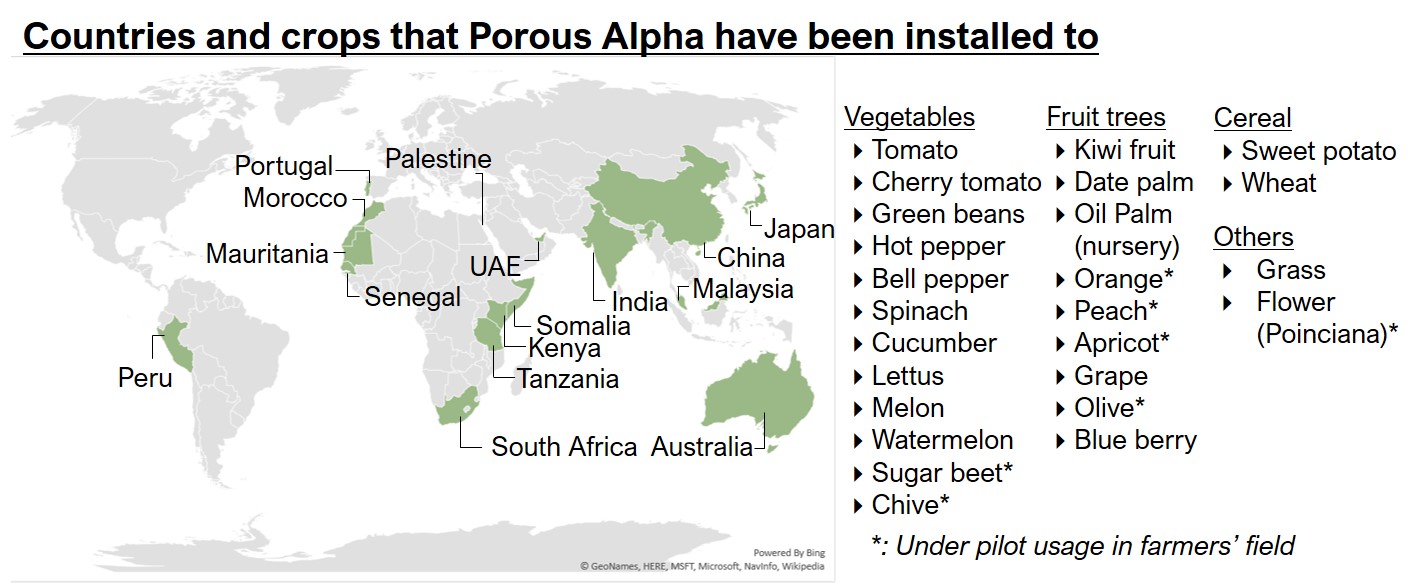

This technology has been installed in many countries for many vegetables and trees so far, to great acclaim.

Major Features and Advantages

I. High Performance

Porous Alpha has realized saving water and/or liquid fertilizer and/or yield increase in fourteen countries, for more than 13 vegetables and more than 9 fruit trees.

For example, it realized 50% water saving alongside with yield increase by about 30% for tomato in Morocco, and the harvest increase of tomato, sweet pepper, spinach, and lettuce, etc by 40 to 60% without water increase in a settlement camp in Somalia (collaboration Project with International Organization for Migration).

II. Ease of Use and Durability

The installing method is just mixing Porous Alpha with the soil, neither the special technic, machine, nor maintenance are required. Porous Alpha’s performance lasts for more than ten years once installed because it, inorganic material, is not bio-degraded. Thanks to the safe and easy technology, this technology can easily be expanded to many countries, especially the areas affected by food shortage and drought.

III. Safety and Harmless

Because the main component of the raw material of Porous Alpha, glass bottle, and solar panel glass, is silica sand and calcium carbonate, the chemical component of Porous Alpha is the same as the natural sand.

Thanks to the patented safe glass foaming technology for the manufacturing of Porous Alpha, there is no negative impact on soil or crop. It complies with Japanese “Environmental regulation regarding the soil pollution”. The soil and crop applied with Porous Alpha is compliant to EU “Council Directive on the protection the environment” and CODEX “General Standard for Contaminations and Toxins in Food and Feed”.

As a safe and harmless product, there is no problem to mix and remain Porous Alpha in the soil for a long time.

IV. Eco-friendly Recycled Products

The huge amount of waste glass is not reused or recycled and landfilled, and it is difficult to recycle glass safely and harmlessly because some of them contain heavy metals.

Thanks to our original patented safe glass foaming technology, we can recycle used glass bottles and solar panel glass to Porous Alpha as a safe and harmless product.

The Tottori University Arid Land Research Center Japan, the University of Tottori is collaborating with Tottori Resource Recycling Inc. to evaluate the effect of porous structure for water preservation in soil. The product has seen successful implementation by International Organization for Migration Somalia and Office Régional de Mise en Valeur Agricole de Souss-Massa in Morocco.

Technology Data

Technology data

Conceivable applications

Water-saving cultivation in arid areas to increase vegetable crop. Limited availability of water for irrigation can restrict growth and production in many crop-irrigated areas, and particularly in semi or arid regions. Porous Alpha gives conclusive solutions.

Competitive advantage

Porous Alpha has the advantage mainly in duration and safe in comparison with the competing product.

For example, superabsorbent polymer and the mineral soil amendments such as vermiculite and zeolite are required to add every few years because superabsorbent polymer lose its water-absorbing capacity. In contrast, Porous Alpha performs for more than 10 years without any maintenance or additional application thanks to its durability. Therefore, Porous Alpha’s long-term cost performance is higher than the other solutions.

Besides, petrochemical-based superabsorbent polymer is remains in a soil even after it doesn’t work in the form of gel, and changes soil physical structure. The natural mining product can contain asbestos and heavy metal depending on its mining site. In comparison with them, since Porous Alpha is manufactured by the patented safety foaming technology and the chemical composition is the same as the natural sand, it is verified that there’s no negative impact on the soil by Porous Alpha.

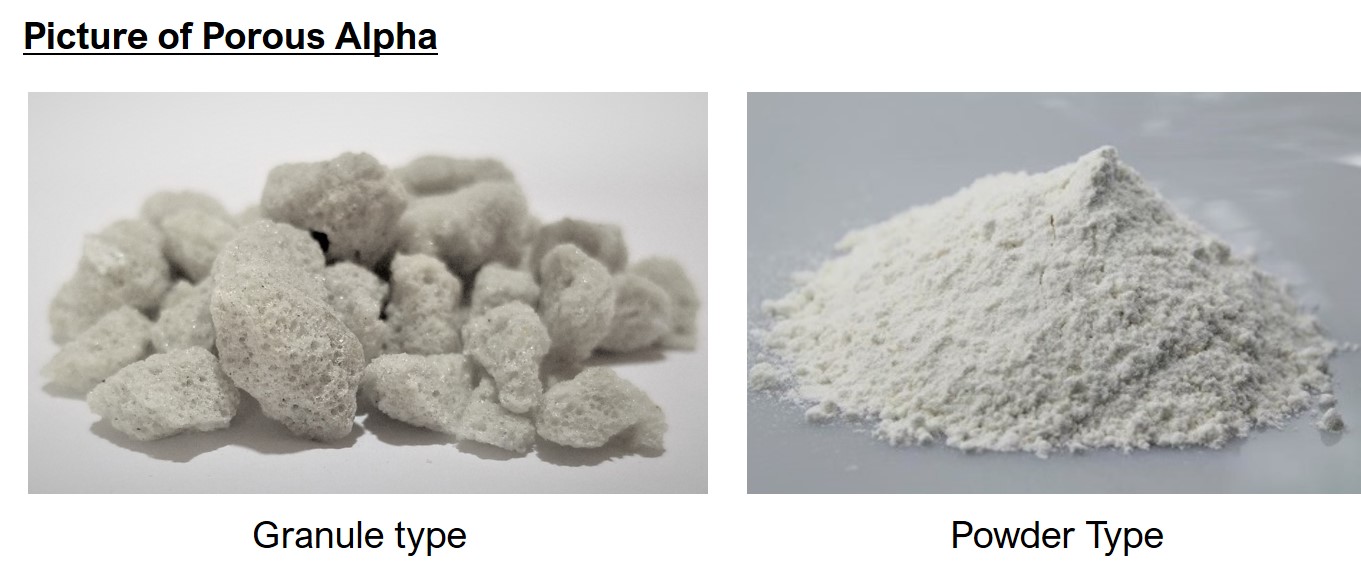

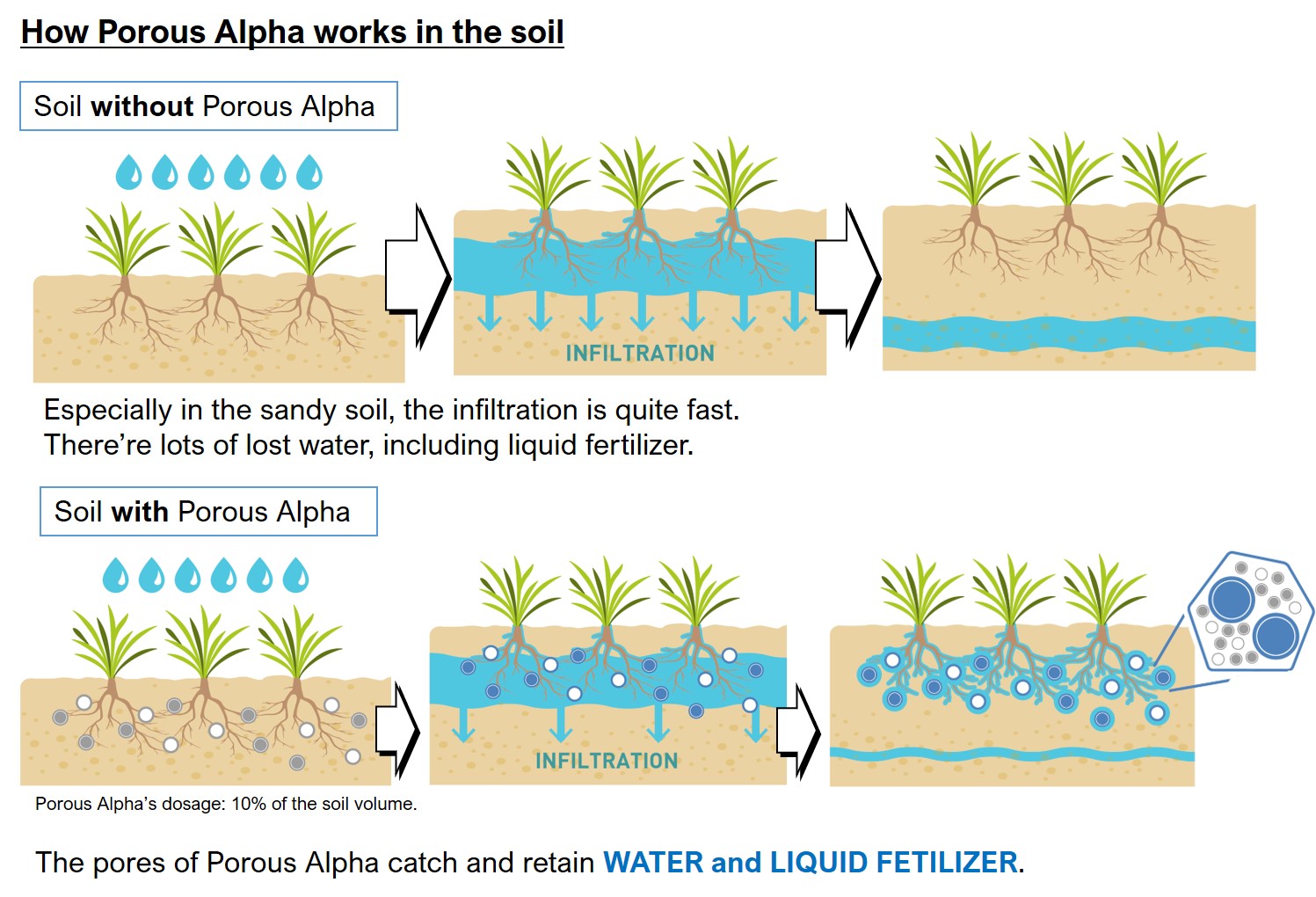

Performance

By just mixing Porous Alpha in the soil, the water retention capacity because the numerous pores in Porous Alpha hold the irrigated water and liquid fertilizer which would be lost by infiltration without Porous Alpha. It realizes 50% water-saving with increased yield, the expansion of farmland without increasing water consumption, and resilient agriculture against climate change, such as drought by keeping/increase of food production in the less rainfall land.

Further information can be found on the company’s website.

Technical maturity

The effect of Porous Alpha for water preservation in soil has been evaluated by Tottori University Arid Land Research Center Japan, the University of Tottori. Porous Alpha has already been installed in fourteen countries, for more than 13 vegetables and more than 9 fruit trees and adopted in many international cooperation projects such as ones of United Nations, JICA, and the local governments.

Conceivable risk

Nil

Information on patent related to this technology

Pat.JP3898116

JP4088930

PCT/JP2018/03500

JP5382657

JP5731791

JP5942141

Company Data

Company data

| Name | Tottori Resource Recycling Inc. | ||||||

| Address | 583, Higashisono, Hokuei-cho, Tohaku-gun, Tottori, 689-2202 Japan | ||||||

| Capital | 40 million JPY | ||||||

| Contact person |

Ms. Mai Nakai |

||||||

| Number of employees | 9 | ||||||

| Date of company foundation | December 2001 | ||||||

| The type of business | Producing foam glass by clean recycling process & Inventing and selling the solutions based on foam glass | ||||||

| Overseas offices | Agadir, Morocco Tottori Resource Recycling Morocco, S.A.R.L | ||||||

| Global Partners |

|

Modality of business transaction

Partnership

for market expansion, distribution and local production of Porous Alpha for implementing the projects such as agriculture, food security, improving malnutrition, climate change ,and so on

Export of product

We can export and transact Porous Alpha from Japan with proposing the appropriate usage method

Licensing of patent

In a phased manner

Attachments

Attachment

The technology was recognized by the Ministry of Economy, Trade and Industry of Japan in the “Climate Change Adaptation Good Practices by Japanese Private Sector in Developing Countries” in March 2023. Please find the description from the page 41.

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Circular Economy (3R)

- Agribusiness Technologies : Production enhancement