A

-Tech Co., Ltd. (hereinafter referred to as A-Tech) holds the manufacturing rights to the "Rotating Blade Type Sorting Machine" under an exclusive patent license agreement with ASD Co., Ltd., the patent holder.

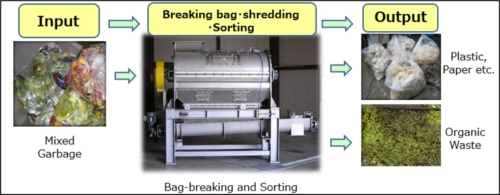

Food waste in packaging containers (such as expired lunch boxes, canned goods, drinks in plastic containers, etc.) can be put into this machine as is, and the food waste and packaging containers (waste plastic, paper) are separated and discharged separately.

Through this sorting process, the packaging containers can be turned into fuel, and the food waste can be used as pig feed or fertilizer.

Separation is the first step for recycling and A-Tech’s technology will contribute to the establishment of sustainable recycling systems in developing countries where almost all wastes are disposed directly to landfills in the developing countries.

Major Features and Advantages

- What makes A-Tech’s Rotating Blade Type Sorting Machine overwhelmingly different from competitors' products is “robustness.” When unexpected objects get mixed into other companies' machines, their shafts (centre axis) often break. A-Tech’s machine has stronger shafts to prevent damage.

- Proven durability: delivery record to local governments supports reliability.

- Compact size for speedy mass processing.

- Processing capacity is 500 kg to 5 tons per hour.

- Easy maintenance.

- Mixed waste can be separated into metals (knives, forks, etc.), plastic bags, cloth, cans, and food waste.

- Input raw materials (food waste, lunch box, etc.) needs simply to be fed into the hopper.

- Depending on the nature and amount of input raw materials, appropriate model (S type, I type, II type, or III type) can be selected.

- Input with wrapping or garbage bags can be separated.

- Cans, PET bottles, etc. can be removed and separated.

- Laminated glass of automotive products, etc. can be separated into glass and interlayer film and recycled.

- High separation rate: approximately 95% separation by weight and bulk density.

- After sorting, the contents can be used for feed, fertilizer, methane fermentation, etc.

- Comes with a cleaning function to ensure hygiene.

Applicability in Developing Countries

- A-Tech has a track record of continuous operation with general waste in China and Thailand (containing glass, cans, bottles, ceramics, spoons, paper, plastic containers, etc.).

Initial Cost and operating cost

The initial plan is to sign contracts with local distributors, establish overseas subsidiaries, and set up inventory management bases. The initial investment is expected to be up to 20 million yen, which will be covered by self-funding and bank loans. In cooperation with distributors and business partners, A-Tech will develop business with local governments and private companies (real estate developers, waste disposal companies, cement manufacturing plants, etc.) as customers.

Availability of infrastructure and resources such as electricity, fuel, water, materials, consumables, etc.

The expected lifespan of the equipment is 7 years, but if used according to the specifications and regular inspections are performed, it has been operating without failure for over 10 years in Japan. Regular maintenance is only greasing the bearings (about 1,000 yen per time, once a month), but it is recommended to keep spare parts (about 200,000 yen) for belts and bearings. Replacement and work after installation will be performed by A-Tech engineers, but the technology will be transferred to the installer or local agent/partner company.

In addition, if a power outage occurs during operation, the device will stop, but if the inside of the machine is checked through the inspection hatch after recovery and there are no clogs, it is possible to resume normal operation. Water is not used except for cleaning, so it is not affected by water outages.

Technical human resources management/Technical backup system

Rotating Blade Type Sorting Machine is mainly made of stainless steel, so stainless steel welding technology and rotating equipment maintenance technology such as bearing replacement are required. In addition to the above-mentioned technology, local production requires the technology to balance the rotors. In addition, electrical and control technology for the operation panel that operates the Rotating Blade Type Sorting Machine is also required.

Issues in Countries and Regions Receiving Technology Transfer

- Waste volume treated at final disposal sites is too large to be managed with the current methods.

- Household and commercial waste are collected together, and due to underdeveloped recycling facilities, almost all waste is disposed of at landfill directly.

To address these issues, it is important to separate mixed waste at the source, intermediate treatment facilities, final disposal sites, etc. By separating the waste, A-Tech believes the following can be achieved:

- Improving quality by converting organic raw materials into feed and compost and removing foreign matter.

- Promoting recycling by using waste plastics as boiler fuel.

Social impacts

Reduction of Environmental Burden: By separating and recycling waste, the amount of waste sent to final disposal sites is significantly reduced, thus reducing the burden on the environment.

Effective Use of Resources: By converting organic waste into feed and compost, and recycling waste plastics, waste is effectively used as a resource.

Improved Economic Effects: Recycling creates new industries, leading to job creation and economic revitalization.

Improved Public Sanitation: Proper waste disposal and sorting will improve unsanitary conditions and public sanitation.

Negative Impacts and Countermeasures: Constructing new sorting and recycling facilities incurs initial costs. It could be mitigated by utilizing subsidies and loans from governments and international organizations to gradually develop facilities.

It is expected that these challenges and solutions will contribute to improved waste management and sustainable development in the countries and regions where the technology is transferred.

Company Data

| Name | A-Tech Co., Ltd. |

| Address |

5F Authentic Hanzomon Building, 2-2 Kojimachi Chiyoda-ku Tokyo, 102-0083 Japan |

|

Website |

https://www.a-tech-eng.com |

| Contact person |

Emi Kemmochi |

| Number of employees | 10 |

| Date of company foundation | January, 2017 |

| Overseas offices | N/A (Note: A-Tech does not have any overseas offices, but we are considering establishing a local corporation at San Jose City in Costa Rica.) |

Modality of business transaction

Direct Investment

In Costa Rica, A-Tech is currently preparing to start local manufacturing. At the first stage of business, A-Tech was considering entering the market through a sales agent (local distributor), but in light of the high local demand, we are now considering establishing a local corporation.

Export of product

In countries where local manufacturing is not available, we will export the product. A-Tech engineers will be on-site to install the equipment. After installation, we will transfer the technology so that A-Tech engineers, the user, or local agents and partner companies can handle maintenance.

Attachments

Schematic illustration of the technology

Rotating Blade Type Sorting Machine can tear open garbage mixed with various items (food residue, paper, plastic, empty cans, PET bottles, forks, and spoons) just by feeding them into the inlet. It is a facility that instantaneously performs shredding and sorting. It has a high sorting rate, is made very strong, and is used by customers for various purposes.

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Waste treatment and management